LEANCURE

Energy Module

ANTICIPATE THE INCREASINGLY COSTLY ENERGY

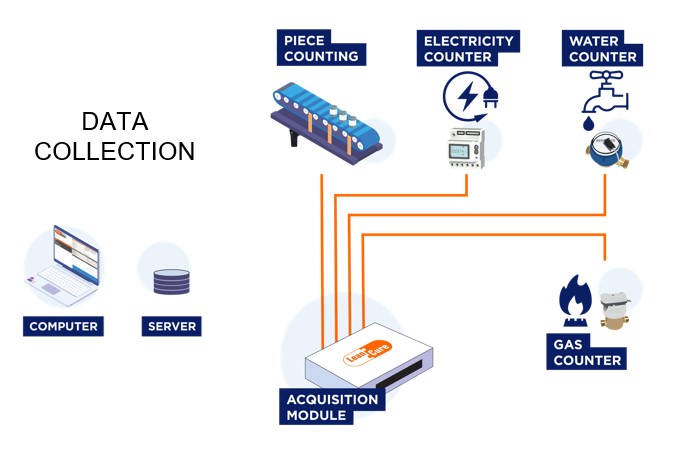

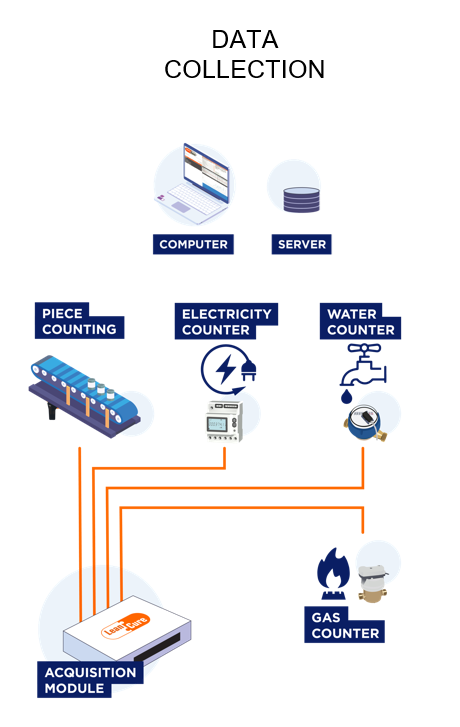

The Energy Module is a real-time energy consumption measurement tool, including:

-⚡electricity

-💧water

-🔥gas…

The Energy Module can monitor a workshop, a production line, or an equipment.

The Energy Module is a real-time energy consumption measurement tool, including:

-⚡electricity

-💧water

-🔥gas…

The Energy Module can monitor a workshop, a production line, or an equipment.

Starting an energy consumption reduction project involves:

➤ Measuring and understanding equipment energy consumption, with a graphical display of consumption curves and the generation of simple summary reports

➤ Modernizing and optimizing the most energy-consuming means

What’s next? How to keep on optimizing?

➤ Defining optimum consumption standards

➤ Daily monitoring with production teams of actual consumption:

- Real-time comparison to standards,

- React and immediately control any deviation through overconsumption alerts based on activity.

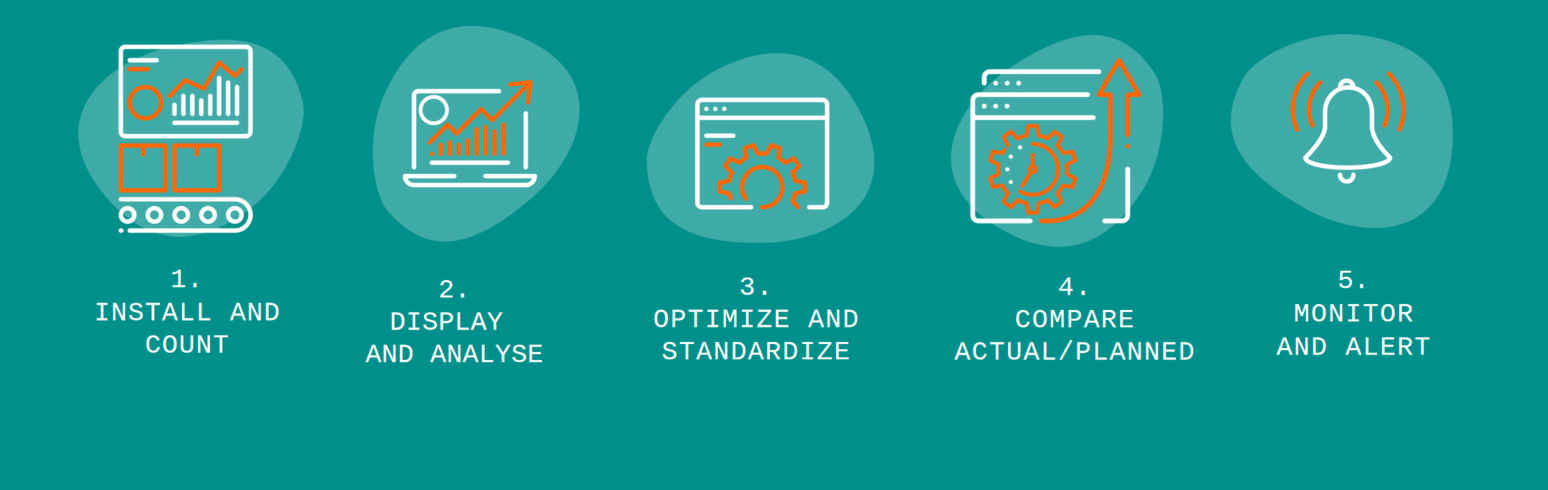

AN ENERGY PROJECT STEP BY STEP

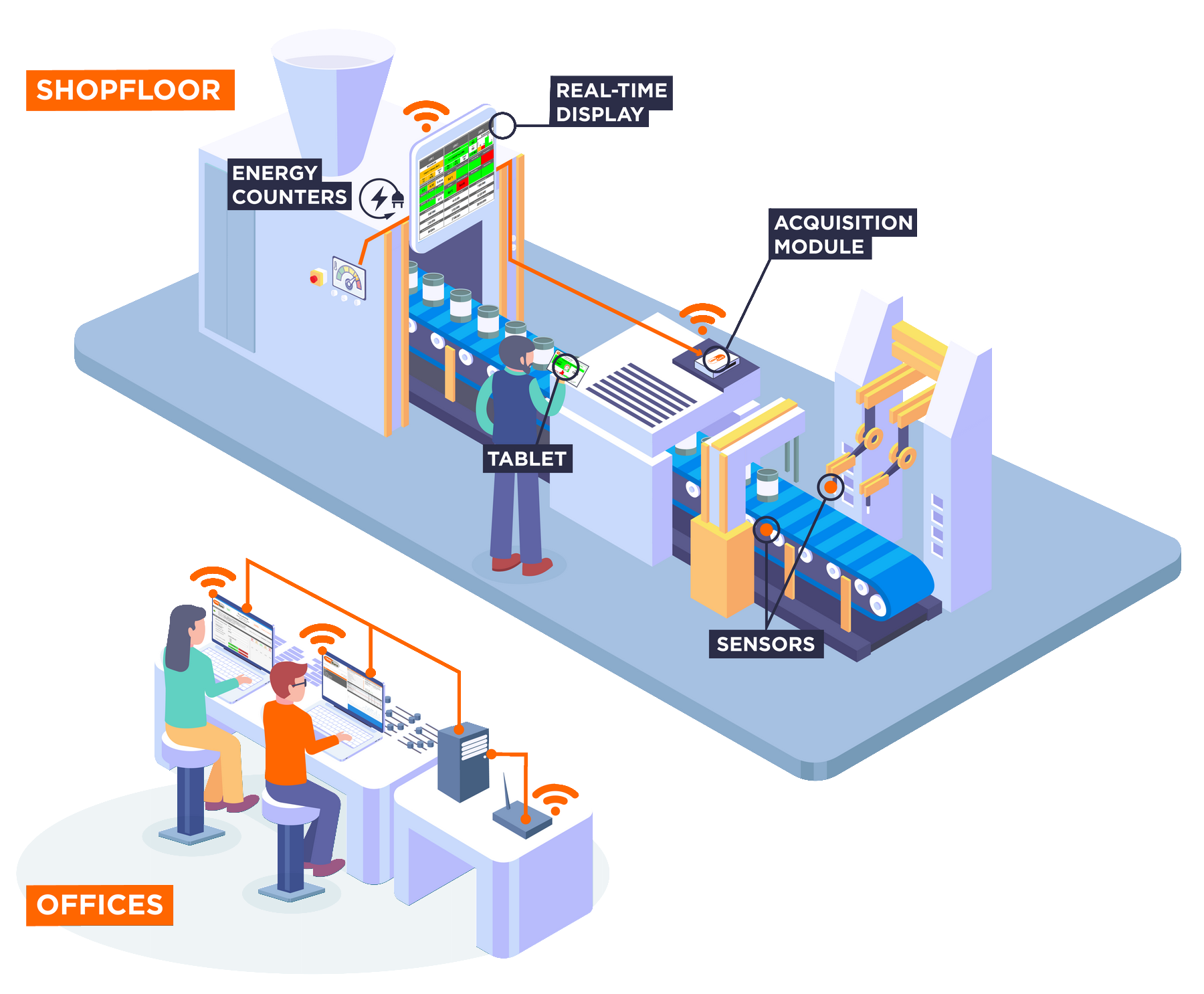

1-Install and Count

➤ Simply equip the machine to be monitored with standard pulse counters* and connect them to Leancure View acquisition modules.

➤ Similar to MES, the acquisition module connected to the factory network will report both piece counts and energy consumption.

*API mode connection available

➤ Calculating formulas can be integrated to generate custom consumption curves.

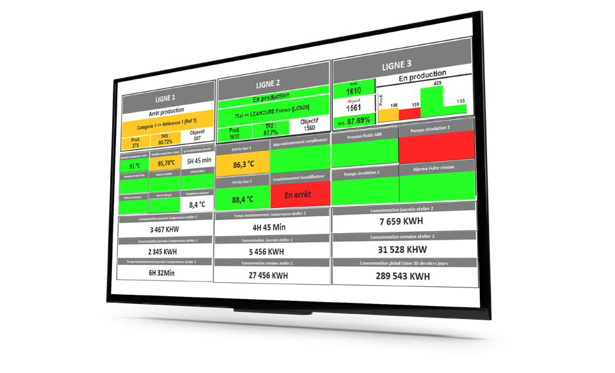

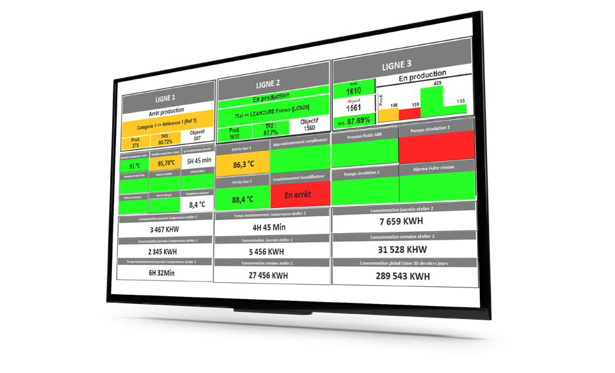

➤ Real-time display of customizable priority indicators.

➤ Periodic KPI reports are available and exportable.

2 – Display and Analyze

➤ Consumption curves are generated within the application.

➤ Consumption data is centralized in the Leancure View software and can be correlated with line performance (energy consumption ratios per pieces produced).

2 – Display and Analyze

➤ Consumption curves are generated within the application.

➤ Consumption data is centralized in the Leancure View software and can be correlated with line performance (energy consumption ratios per pieces produced).

➤ Calculating formulas can be integrated to generate custom consumption curves.

➤ Real-time display of customizable priority indicators.

➤ Periodic KPI reports are available and exportable.

3 – Optimize and Standardize

➤ Analyzing energy consumption allows for optimization and standardization of equipment needs.

➤ Consumption standards related to machine operating states (running, stops, breakdowns, daily cleaning, weekly cleaning, etc.) are then defined.

➤ These standards are configured in the Leancure View tool and serve as a reference base for target consumption.

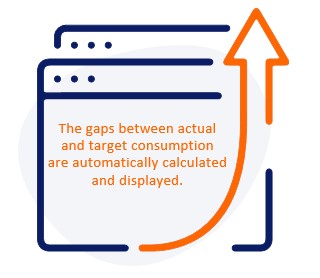

4 – Compare actual/planned

➤ Energy consumption is known in real-time

➤ Based on consumption standards and machine operating states: target energy consumption is automatically calculated

5 – Alert

➤ Consumption deviations are automatically detected

➤ Configurable alerts are sent to operators and managers:

PILOT TRIAL

ADVANTAGES OF THE ENERGY MODULE

Simple and quick installation

Comparison between actual and planned consumption

Graphical display of consumption curves

Simple summary reports

Simplified declaration of the tertiary energy eco-decree

Real-time overconsumption alerts

Following the same principle as the TRS performance module and the quality module,

the energy module can be installed in just one day and is available on your intranet with unlimited access.