What is an MES ?

A ME.S or Manufacturing Execution System is a tool for automated production tracking. Its role is to supervise the machines and the operators by providing a complete follow-up of the manufacturing information coming from the shop floor. It follows the “Know, Analyze and Improve” scheme, common to all continuous improvement approaches. It is the central point of all execution data.

Also, by gathering all the production data in real time, the ME.S gives a view on the work in progress and the yields of the references/PO. At the heart of Industry 4.0, the MES offers multi-source and multi-media interconnectivity, the necessary basis for the digitalization of manufacturing processes. In conclusion, it participates in the digital transformation of factories by bringing them greater agility in their production. This is the origin of the term Smart Manufacturing : the intelligent and connected production plant, where data circulates without limits.

Our system Leancure Vies MES ?

Based on the latest web technologies, Leancure View is a production and quality tracking system. A visual management tool 100% oriented on productivity, Leancure View MES offers readable monitoring tables, easy to use and accessible remotely.

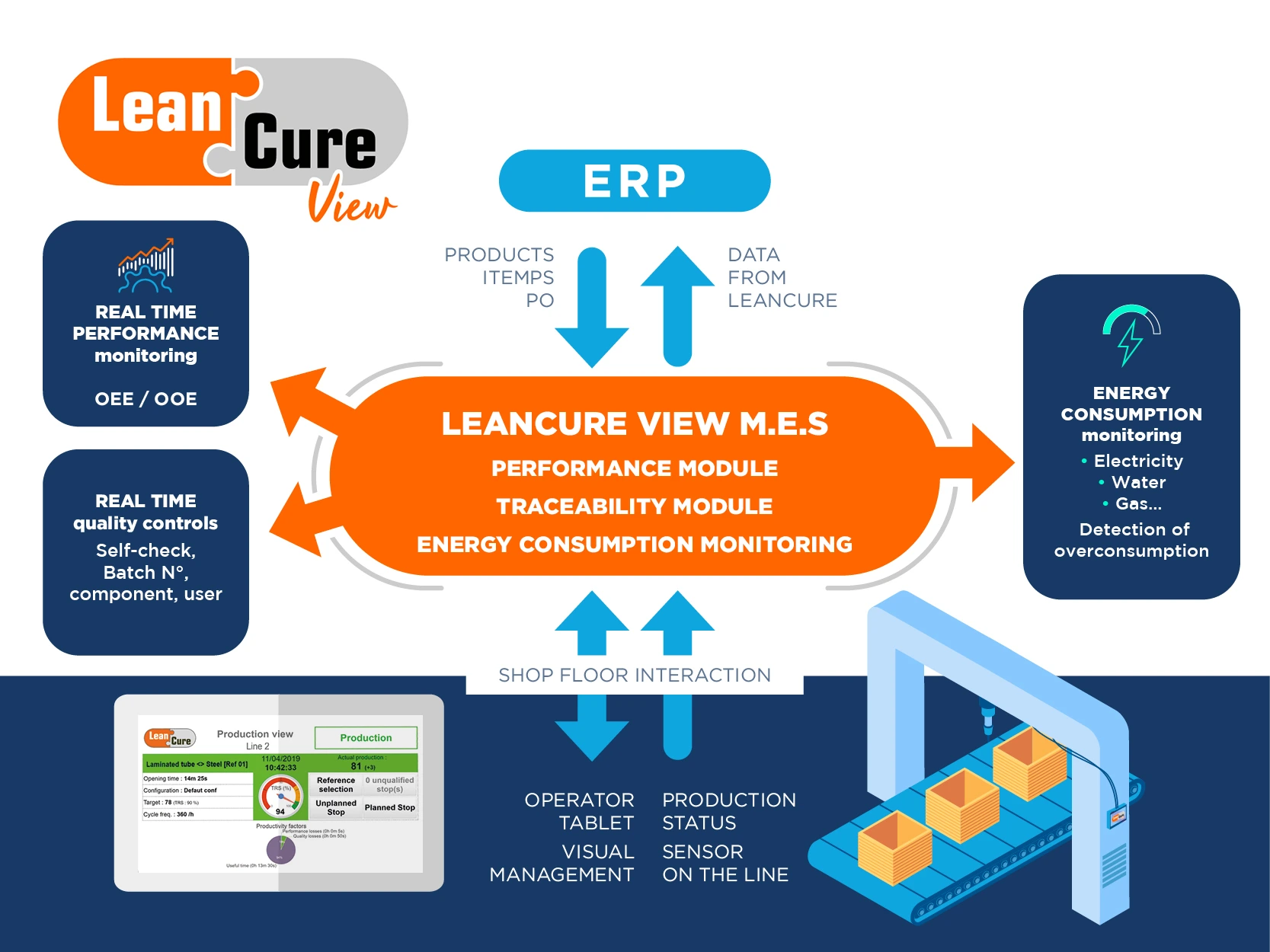

Our web application is composed of 2 interdependent modules : Performance, for real-time productivity monitoring and Traceability – Self- check, for quality control on production lines.

Our tool is flexible and easy to use, connects to existing sensors on your production lines and interacts with the operator via a tactile tablet in the shop floor. Access to data and analysis reports is directly available on the administrator application and is unlimited throughout the plant. Our system can communicate with other software such as ERP, complementary software to MES.

Leancure View MES on your production lines

Leancure recovers data directly from the sensors already existing on your line while remaining independent of the automats. With a simple wifi or ethernet connection, we connect the Leancure equipments without stopping the production of your line and in a few hours the system is set and functional. Thanks to the connected objects around the line, the productivity is broadcasted in real time in the shop floor and the offices, the operators can interact with the system and the managers can access the data to analyze them. The digitization of data is automatic, no more paper around the line.

Leancure View is a low-intrusive solution that can be easily adapted to many situations in the field, at a controlled cost.

For both production and quality monitoring, Leancure View’s easy-to-use analysis tools help you build your improvement plans and production reports.

Leancure allows you to improve your productivity thanks to a flexible tool, easy to install, with a simple, practical and user friendly interface.

The modules of our solution Leancure View MES

3 modules are proposed on our application, they can work together or separately according to your needs.

PERFORMANCE MODULE :

To track and analyse your productivity in real time.

ENERGY MODULE :

To measure and optimize your energy consumption in real time.

TRACEABILITY MODULE :

To track easily your quality in the shop floor.